As global manufacturing accelerates its transformation towards intelligent and autonomous operations, industrial robots have become a core engine for industrial upgrading. In this competition concerning technological dominance and future competitiveness, Kewei Robotics has stood out from the ranks of domestic industrial robot manufacturers thanks to its focus on niche markets and its strength in independent innovation. With its advanced technology and comprehensive services, it is reshaping the market landscape of industrial automation in China.

01 Data Anchoring: Solidifying Market Dominance in Niche Sectors

Kewei leverages strategic planning and authoritative certifications to forge a significant position in niche sectors.

Comprehensive Cultivation, Setting the Market Standard

▣ In the niche sector of material handling and palletizing, Kewei holds a dominant 70% domestic market share, providing core support for enterprise capacity upgrades;

▣ Deeply cultivating core sectors such as auto parts, cold chain logistics, and food and beverage, becoming a key partner for the intelligent transformation of many manufacturing enterprises.

Certifications, Building a Solid Foundation for Development

▣ As a "seed enterprise" nominated and nurtured for listing by Tai'an City, Kewei has successively obtained authoritative recognitions such as Shandong Provincial Innovative SME and Shandong Provincial Specialized and Innovative SME;

▣ Passed ISO9001 quality management system certification, achieving a level-two standard in digitalization, and relying on the regional manufacturing innovation ecosystem, built an integrated industrial chain capability from R&D to implementation.

02Technology-Driven Success – Breaking Foreign Monopoly with "Chinese Chips"

The depth of a market stems from the strength of its technology. Driven by independent innovation, Kewei has overcome critical technological bottlenecks, forging a technological benchmark for "Made in China 2025."

Patent Foundation, Innovation Breakthrough

◈ Holding multiple national patents, core control technologies and programming software are fully self-developed, freeing the company from dependence on foreign technology;

◈ Successfully overcoming industry challenges of "domestic production of core components and independent development of key technologies," its graphical operating system, gesture modeling + 3D preview, enables highly efficient production with "product change in 5 minutes and production line change in 30 minutes";

◈ Jointly establishing an industry-university-research innovation center with Shandong University, focusing on the integrated application of "robotics+", continuously promoting the localization of key technologies and performance iteration.

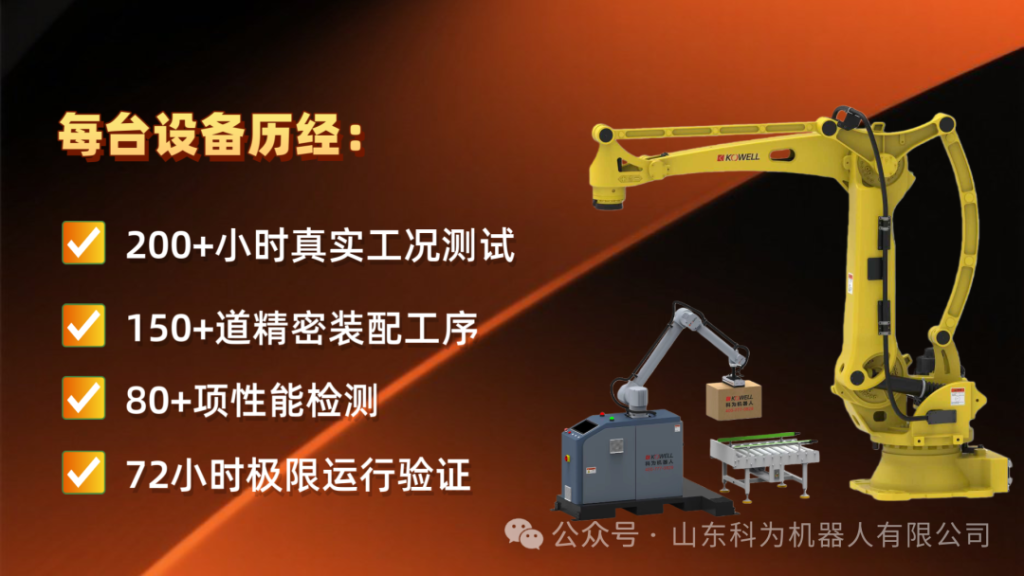

Product as the blade, performance defined

◈ Flagship models such as the KW1120M four-axis heavy-duty robot achieve a significant breakthrough in hourly throughput while maintaining motion accuracy ≤±0.2mm, improving efficiency by more than 25% compared to similar products in the industry;

◈ The fourth-generation collaborative palletizing robot, equipped with a "zero-programming" graphical system and EU CE certified safety protection, has become a "cost-reduction tool" for the intelligent transformation of SMEs.

03 Ecosystem Empowerment: Building Industry Collaboration Through "Products + Services"

True industry participants go beyond product delivery; they are involved in ecosystem co-construction. Kewei, with a customer-centric approach, has created a collaborative system driven by both "products" and "services."

Service Support, Full-Process Response

◉ Establishing over 50 service outlets nationwide, linking two R&D centers, to build a service system with "48-hour response and full-cycle protection";

Collaborative Win-Win, Empowering the Entire Chain

◉ Providing customers with "quantifiable, implementable, and replicable" automation solutions, achieving the transformation goals of "affordable, easy to use, and quick results";

◉ Promoting a collaborative development model of "core guidance + full-chain cluster," extending from single equipment supply to value co-creation across the entire industry chain.

04 Future Strategy: Leveraging the Edge of Chinese Intelligent Manufacturing to Expand the Global Industrial Landscape

Maintaining market position requires a forward-looking vision. Kewei aims to be on par with international brands by 2025, deepening its global value chain collaboration and internationalization strategy.

❑ Deepening R&D and Expanding Boundaries: Continuously increasing R&D investment, focusing on core technology iteration and upgrading, seizing global high-end market share, and enhancing international core competitiveness;

❑ Global Expansion and Intelligent Manufacturing Going Global: Deepening its international strategic layout, promoting independently developed products and services to the global market, gaining global recognition for the technological strength of "Made in China," and building a globally renowned robot brand;

❑ Ecosystem Co-construction and Collaborative Development: Deeply collaborating with upstream and downstream enterprises and research institutions to jointly build an "open, collaborative, and win-win" new industrial ecosystem, empowering industrial upgrading with its "specialized, refined, and innovative" core genes, and contributing to the global rise of "Made in China."

With unwavering strength, fulfilling the promise of the times

From robust data to technological independence, from product supply to ecosystem empowerment, Kewei Robotics' market position is rooted in the fertile soil of "Made in China 2025," grown through relentless commitment to independent innovation, and demonstrated through its responsible commitment to industry empowerment. As "Made in China 2025" climbs to the top of the global value chain, Kewei is forging ahead with determination, using patents to build technological barriers, using data to demonstrate market strength, and using services to connect the future of the industry, writing a new chapter for Chinese robot brands.

Online Consultation

Hello, the current customer service is offline. You can leave your contact information and the staff will respond to you as soon as possible!