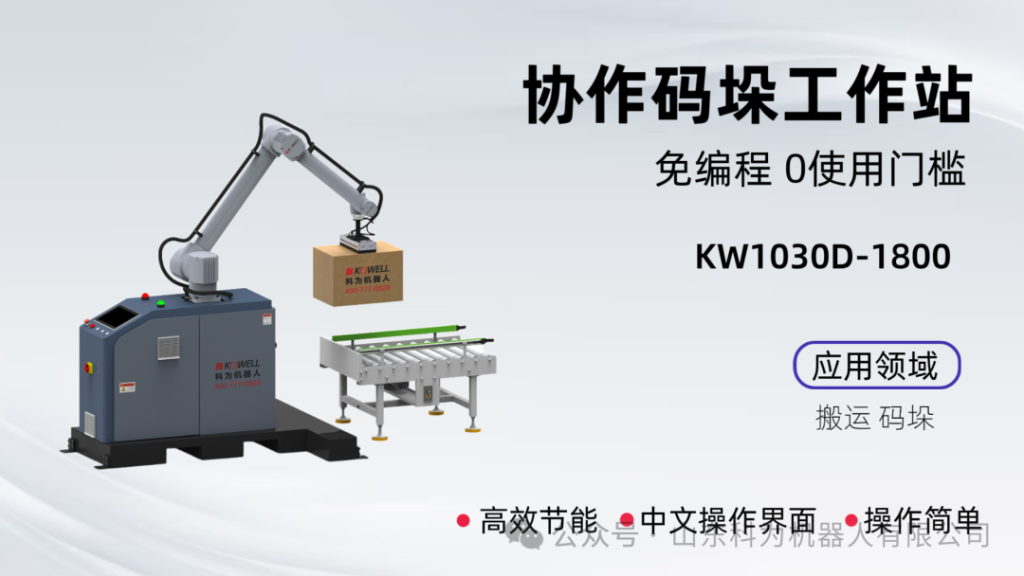

In today's fiercely competitive food industry, improving production efficiency, ensuring hygiene and safety, and rapidly responding to market demands have become core issues for enterprise survival and development. When traditional palletizing methods are mired in efficiency bottlenecks and safety hazards, Kewei Robotics' collaborative palletizing workstation, with its innovative "zero-programming" design and outstanding collaborative performance, has become a key engine for the intelligent upgrading of food enterprises, helping them seize opportunities and win in this transformation.

I. Technological Innovation: Reconstructing the Core Logic of Production Mode

01 "Zero-Programming" Human-Machine Collaboration: Disrupting Traditional Division of Labor

The workstation is equipped with Kewei's self-developed graphical intelligent operating system and a dedicated intelligent palletizing process package. Through an intuitive drag-and-drop interface and preset process templates, ordinary workers can easily complete new task configurations without needing professional programming knowledge, achieving efficient switching of "product change in 5 minutes, production line change in 30 minutes."

02. Multi-faceted Safety Protection: Building a Reliable Production Protection System

Relying on a Level 10 anti-collision detection system and a 16-channel safety I/O redundancy architecture, collision-based shutdown constructs a safety barrier. The high-level protection design effectively resists common food production environments such as moisture and dust, ensuring core components operate stably for extended periods under complex conditions, safeguarding continuous production.

03. Multi-dimensional Flexible Adaptability: Flexibly Responding to Market Demands

◈ Compatible with All Material Categories: Addressing the diverse packaging needs of the food industry, it integrates suction cups, adaptive grippers, and other flexible grasping solutions, achieving precise grasping and stable stacking of various material forms, including cartons, bags, and drums.

◈ Intelligent Lifting System: Dynamically adaptable to multi-level production lines with varying heights, and coupled with high-precision servo drives, it achieves "one-machine compatibility" across multiple operational scenarios, significantly improving equipment utilization.

◈ Compact and Efficient Design: Adopting an integrated design, the structure is compact, occupies a small area, and is lightweight and flexible, adapting to the generally compact layout requirements of food factories. This reduces energy consumption, achieving high returns on investment.

II. alue Realization: Helping Enterprises Achieve Three Major Breakthroughs

◉ Efficiency Breakthrough: Palletizing speed is 3-5 times faster than manual labor, achieving seamless production line integration, significantly increasing overall capacity, and easily handling peak order volumes.

◉ Cost Breakthrough: Reduced labor input, reduced training costs, increased equipment utilization, accelerated value transformation, and tangible results.

◉ Quality Breakthrough: Precise grasping and stacking control reduces product packaging damage rates, minimizes human contact, reduces the risk of cross-contamination, meets the stringent hygiene requirements of the food industry, and helps enterprises build a strong brand reputation.

As the food industry enters the deep waters of intelligent transformation, Kewei is reconstructing production logic with technological breakthroughs: breaking down operational barriers with "zero programming," responding to market changes with flexible intelligent manufacturing, and safeguarding the foundation of production with comprehensive safety measures. When efficiency and flexibility are no longer contradictory, and human-machine collaboration has become the norm, it is not only a "production line accelerator" for improving efficiency, but also a "value engine" driving the leap from traditional manufacturing to intelligent manufacturing. In the future, Kewei Robotics will continue to cultivate technology with ingenuity, drive change with innovation, focus on the intelligent needs of the food industry, continuously iterate its products and solutions, inject new momentum into the global food industry, and promote the industry towards a new era of greater safety, efficiency, and intelligence.

Online Consultation

Hello, the current customer service is offline. You can leave your contact information and the staff will respond to you as soon as possible!