Currently, the manufacturing industry is at a critical stage of transformation and upgrading. In traditional palletizing operations, efficiency is often difficult to improve continuously, and may even decline with increased working hours. High staff turnover in palletizing positions requires companies to continuously invest significant resources in recruitment and training, while the inherent safety hazards of manual operation also pose certain risks to production and operations.

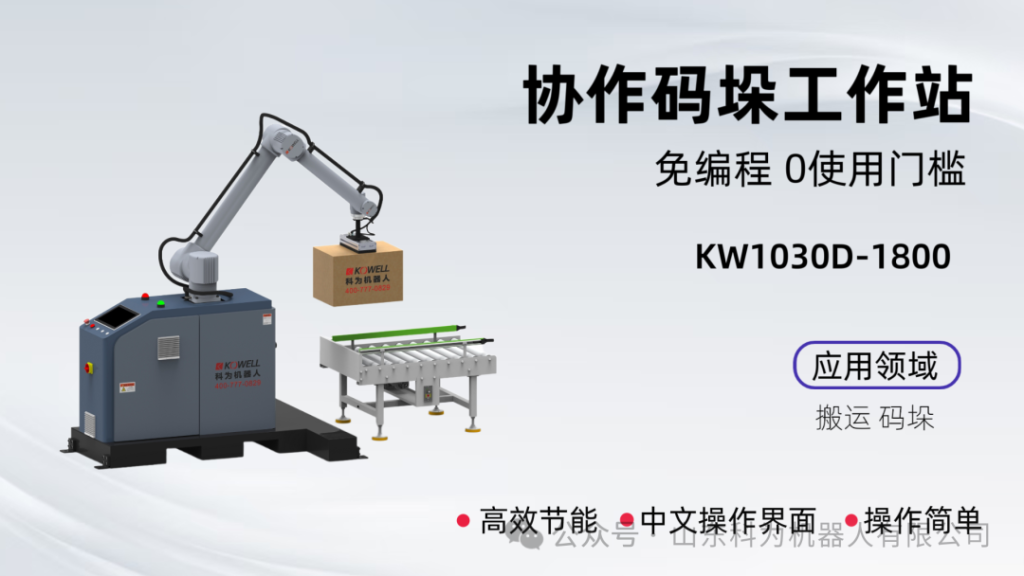

To address these common industry challenges, Kewei Robotics' collaborative palletizing workstation, with technological breakthroughs at its core, provides manufacturing enterprises with a feasible intelligent solution—assisting them in addressing multiple pain points in the palletizing process, helping to achieve continuous cost control, efficiency improvement, and quality enhancement, and empowering the intelligent transformation of the manufacturing industry.

PART 01 Improved Space Utilization

Compact Body, Efficient Output

❏ Compact Integration, Freeing Up Space: Adopting a highly integrated compact design, it effectively reduces the equipment's footprint, freeing up factory space resources, especially suitable for modern production lines with high space utilization requirements.

❏ Flexible Movement, Efficient Stacking: Multi-degree-of-freedom joint modules support flexible bending, extension, and rotation, enabling complex stacking arrangements, helping to optimize three-dimensional space utilization and achieving "small size, big impact."

PART 02 Significantly Improved Production Flexibility

Agile Response, Rapid Changeover

❏ Convenient Changeover, Intelligent Operation and Maintenance: Achieving "5-minute product changeover, 30-minute production line adjustment"; operators only need to input basic parameters such as pallet size and stack shape, and the system automatically generates the stacking path, achieving "zero programming operation, everyone can operate and maintain."

❏ Multi-Shape Adaptability, Stable Grip: Compatible with flexible gripping solutions such as suction cups and claws, adapting to different material shapes such as cartons, bags, and drums.

❏ Intelligent lifting, multi-dimensional coverage: The intelligent lifting column system can dynamically adapt to production line stages of different heights, and with high-precision servo drive, it supports coverage of multi-dimensional operation scenarios.

PART 03 High Safety and Reliability Human-Machine Collaboration for Safer Operation

❏ Multiple Protections for Safe Collaboration: Built-in safety protection system with anti-collision detection mechanism and 16 safety I/O interfaces; immediate stop upon collision. An emergency stop button is also provided, offering multiple safety guarantees for human-machine collaboration.

❏ High Rigidity Structure for Economical Maintenance: Utilizing a high-rigidity structure and precision RV transmission system, the equipment's load capacity and impact resistance are improved, ensuring long-term stable operation. Modular design extends maintenance cycles and reduces maintenance costs.

The Kewei Collaborative Palletizing Workstation, through its advantages in space optimization, flexible production, safety and reliability, and economic benefits, provides manufacturing enterprises with a complete and implementable intelligent palletizing solution. It not only helps enterprises address the efficiency, manpower, and safety challenges of traditional palletizing operations but also helps create real economic value.

As the manufacturing industry moves towards intelligence and flexibility, Kewei Robotics will continue to advance technological breakthroughs and application scenarios, providing customers with more advanced and reliable intelligent solutions to help Chinese manufacturing achieve high-quality and sustainable development and move towards a new stage of intelligent manufacturing.

Online Consultation

Hello, the current customer service is offline. You can leave your contact information and the staff will respond to you as soon as possible!