The stamping workshop, as a critical link in manufacturing, significantly impacts a company's market competitiveness in terms of production efficiency and quality. Facing the wave of intelligent transformation in manufacturing, traditional stamping production faces multiple challenges in precision control, flexible adaptation, and operational stability. Shandong Kewei has launched an intelligent loading and unloading system to address these pain points.

Bottleneck 1: Dual constraints of precision and operational risk under high-speed stamping

The high-speed operation of stamping processes presents two difficulties for manual operation: prolonged repetitive work easily leads to fatigue, affecting the consistency of workpiece positioning; and personnel working near heavy stamping equipment face risks such as accidental contact and material splashing.

Kewei Solution: Precise Control + Comprehensive Protection Design

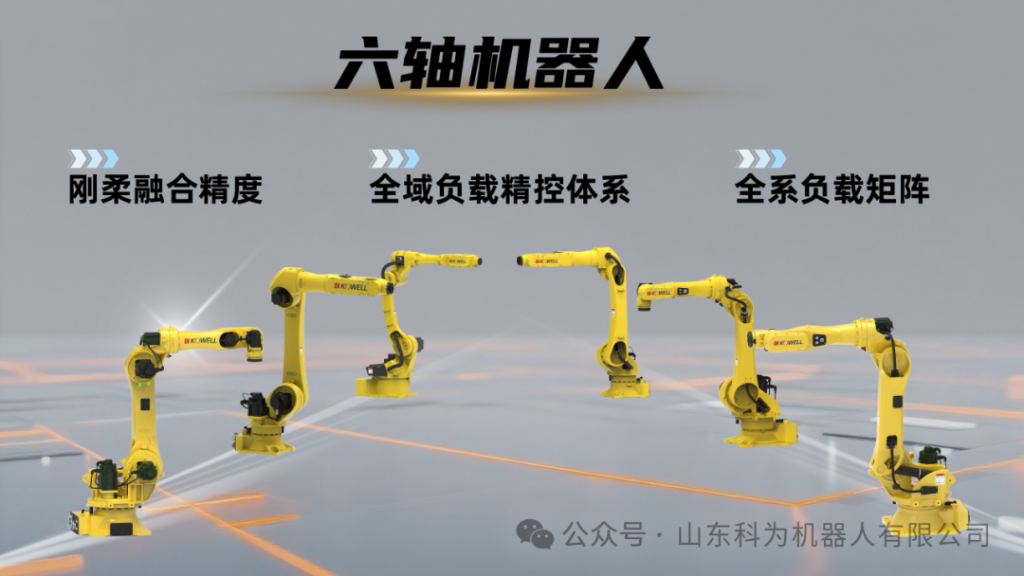

High-precision stable control: Adopting a high-rigidity body design helps mitigate mechanical vibration and load deformation. Combined with high-dynamic servo drives and precision RV reducers, it helps reduce deformation during the processing of heavy materials;

Unmanned operation: The six-degree-of-freedom joint structure flexibly adapts to workpieces of different specifications, and with customizable end effectors, it can replace manual labor in high-risk work areas.

Bottleneck 2: Shortcomings in flexible adaptation under multi-variety orders

Current market demand is shifting towards rapid iteration of multiple varieties and small batches. Traditional stamping lines are mostly designed with fixed models, requiring re-debugging and tooling changes during production changes, which is not only time-consuming but also limited by site layout and difficult to adjust flexibly.

Kewei Solution: Agile Production Change + Compact Integration

Rapid adaptation: Customizable end effectors (suction cups, grippers, etc.) flexibly adapt to diverse stamped parts, helping to reduce material damage;

Compact integration: Models covering multiple load ranges, with a compact body design to adapt to limited space, making it easy to integrate into existing production lines and optimize layout adaptability.

Bottleneck 3: Challenges of stable operation in harsh working conditions

The common presence of oil, dust, temperature and humidity fluctuations, and continuous vibration in stamping workshops places extremely high demands on equipment durability and stability. Ordinary equipment is susceptible to environmental corrosion and failure, and unplanned downtime can affect production rhythm and capacity.

Kewei Solution: Environmentally Adaptive Design + Intelligent Operation and Maintenance

Wide-range weather-resistant design: Features a wide operating temperature range of 0℃-45℃ and a high protection rating, effectively resisting oil, dust, and moisture corrosion;

Intelligent early warning and maintenance: Built-in self-developed monitoring system detects potential equipment risks, helping to reduce unplanned downtime.

Support System: Three Major Systems Ensure Reliable Quality

The performance of Kewe Intelligent Loading and Unloading Systems relies on a systematic support system encompassing technology, research and development, and service:

Industry-Academia-Research Collaboration:A joint "Shandong University-Kewe Robotics Research Center" has been established with Shandong University, focusing on the research and development of intelligent solutions;

Core Patented Technology: Possessing multiple national patents, building a core technology protection system, and certified by the ISO9001 international quality system;

Intelligent transformation is not merely simple equipment upgrades, but a systematic optimization of production processes. Kewe Intelligent Loading and Unloading Systems, focusing on precision, flexibility, and stability, address the actual needs of stamping workshops, assisting enterprises in achieving coordinated development in efficiency, safety, and cost, and driving intelligent manufacturing practices to a new stage.

Online Consultation

Hello, the current customer service is offline. You can leave your contact information and the staff will respond to you as soon as possible!