Empowering Intelligence, Creating a Transformative Future

Kewei Robotics Invites You to Witness a New Chapter in Embodied Industry

Exhibition Overview

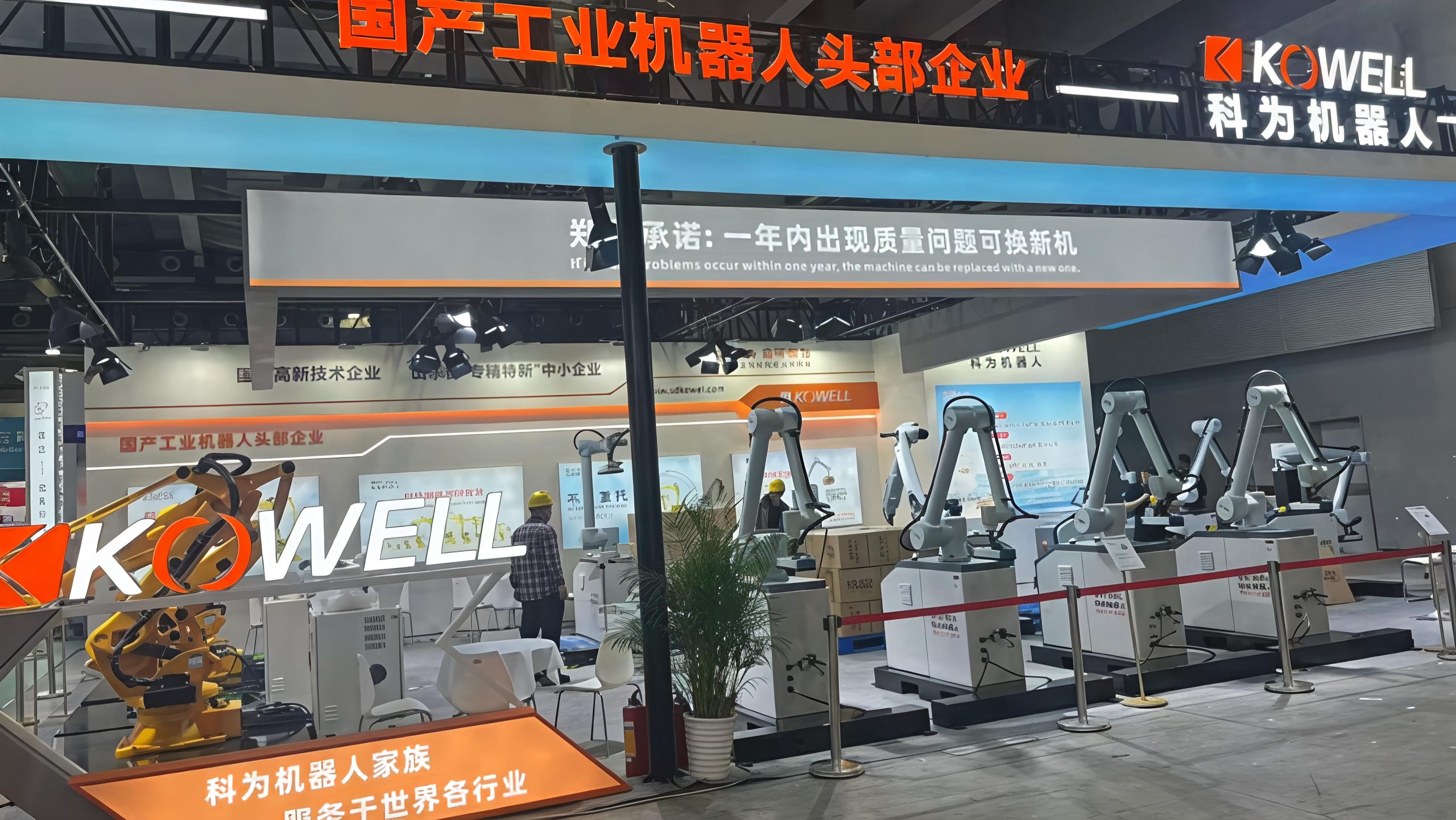

As industrial intelligence enters its twilight years, each technological iteration reshapes the future of production. On September 23, 2025, the Shanghai International Industrial Expo will usher in a new chapter. Shandong Kewei Robotics Co., Ltd., an innovative practitioner deeply engaged in the field of industrial automation, will showcase its full range of core technologies and scenario-based solutions at Booth C190 in Hall 7.1H. We sincerely invite industry leaders and technology pioneers to join us in discovering cutting-edge technology and discussing the future of intelligent manufacturing.

Technology Matrix:

High-Dimensional Motion Control × Adaptive Flexible Manufacturing Paradigm

01 Six-Axis Robot Cluster: Full-Range Load Coverage, Reshaping Performance

The Kewei six-axis industrial robot series features five core models, encompassing a full range of load capacities from 12kg to 220kg. These robots are versatile and adaptable to demanding industrial scenarios, from high-precision 3C electronics assembly to heavy equipment and heavy material handling. All products come standard with Kewei's proprietary high-dynamic motion control algorithm, achieving ±0.05mm repeatability. Combined with a 20% improvement in dynamic response, this algorithm overcomes the challenge of accuracy degradation in heavy-load scenarios.

Leveraging the deep integration of high rigidity and adaptive compliance, this series not only meets existing industrial needs but also continues to push the boundaries of automation efficiency in multi-dimensional and complex working conditions, providing a scalable, future-proof core execution unit for intelligent manufacturing.

02 Intelligent Welding Workstation: High-Precision Fusion Manufacturing Solution

Kewei's high-precision intelligent welding workstation integrates adaptive real-time weld seam tracking technology and a multi-pulse waveform precision welding power supply system. Compatible with six welding processes, including GMAW, Laser, and Hybrid, the robot boasts excellent generalizability for welding multiple materials, including carbon steel and aluminum alloys. Through multimodal sensor fusion and real-time trajectory optimization, it achieves 98.7% weld seam consistency.

For key applications such as lightweight automotive manufacturing and welding of core structural components for construction machinery, the robot provides intelligent welding robots with both ultra-high stability and adaptability, enabling the manufacture of high-value-added products.

03 Intelligent Palletizing System: Cognitive Interactive Decision-Making Core

Kewei's intelligent palletizing robot integrates the "One-Touch Palletizing Intelligence System (OPIS)." Based on a graphical human-machine interface (HMI) and a self-learning parameter optimization model, this system enables zero-programming pallet design and automatic path planning.

This significantly reduces the technical barriers and time costs of automated deployment (deployment efficiency increased by ≥60%), providing an efficient, agile, and profitable path for intelligent transformation and upgrading for small and medium-sized manufacturing enterprises.

04 High-Speed Palletizing Robot for Barreled Materials: A Powerful Logistics Engine

Kewei's high-speed palletizing robot for barreled materials is designed specifically to meet the demanding logistics requirements of high-throughput, continuous production lines in industries such as chemicals and food and beverages. Leveraging ultra-high-speed servo motion control technology and precise positioning capabilities, it enables high-speed, stable, and damage-free transfer and stacking of barreled materials.

It significantly optimizes back-end logistics cycle times, significantly improving overall material turnover efficiency and storage space utilization, and is a key component in building a modern, unmanned smart factory logistics system.

The Ultimate Kewei Experience:

Communication through Warmth, Craftsmanship through Details

While focusing on core technology, we also understand that warm communication fosters deeper resonance.

We firmly believe that outstanding technology demonstrations require in-depth interaction and a comfortable exchange environment. To this end, the Kewei booth has meticulously designed the "Kewei Smart Sharing Space," creating an exclusive and comfortable atmosphere for discussions and offering a moment of peace and tranquility for our distinguished visitors.

Craft Beer Tasting: Enjoy Taishan Original Beer, specially selected from Mount Tai, brewed using traditional methods. Savor the mellow aroma of time and malt.

Elegant Tea Break: Enjoy exquisite refreshments such as flavorful grilled sausages, hand-picked seasonal fruits, artisan ice cream, and freshly baked popcorn, prepared by the Kewei team, adding a touch of delight to your taste buds amidst the technological feast.

Private Negotiation: In this quiet and elegant exclusive area, engage in in-depth conversations and strategic discussions with the Kewei technical team on industry trends, technical challenges, and customized solutions.

We hope that these meticulously crafted details will serve as heartwarming footnotes beyond technical discussions, ensuring that every visit combines commercial value with human warmth.

From technical specifications to application scenarios, from algorithm innovation to industry empowerment, the Kewei Robotics booth serves not only as a showcase for core technologies but also as a platform for exchanging industry insights. We look forward to meeting fellow industry players and innovators interested in intelligent manufacturing—here, witness the redefinition of the boundaries of precision manufacturing, and explore the possibilities of industrial automation through relaxed conversations.

With technology as the pen, customer value as the ink, and scenarios as the scroll, Kewei Robotics invites you to jointly chart the next chapter of industrial intelligence.

We await your arrival at the Shanghai Industrial Expo on September 23rd!

We cordially invite you to join us in the celebration of intelligent manufacturing!

Exhibition Dates

September 23-27, 2025

Kewei Booth

7.1HC190

Exhibition Location

National Exhibition and Convention Center (Shanghai Hongqiao)

Online Consultation

Hello, the current customer service is offline. You can leave your contact information and the staff will respond to you as soon as possible!

![[Preview] Empowering Intelligence, Unlocking the Key to “Creating a Transformative Future”—Kewei Robotics Invites You to Witness a New Chapter in Embodied Industry!](https://cdn.cnyandex.com/kw_en/uploads/bannercon-2.jpg)