In the long manufacturing chain, handling is often underestimated. While less visible than core processes, it continuously supports the operation of production. With the restructuring of manufacturing systems, handling units are gradually shifting from a marginal role to a logical hub. The effects of these structural adjustments are unleashing new power within the overall manufacturing landscape.

I. Overlooked Nodes and Systemic Transformations

Traditional manufacturing systems often view handling as a simple logistical process, using manual labor or fixed equipment to transfer materials. However, as manufacturing demands greater flexibility, stability, and controllability, the role of handling units has begun to shift. They are no longer simply "execution," but a core link closely linked to process integration, information synchronization, and pacing. Behind these structural adjustments lies a shift in handling logic from local optimization to systematic reshaping.

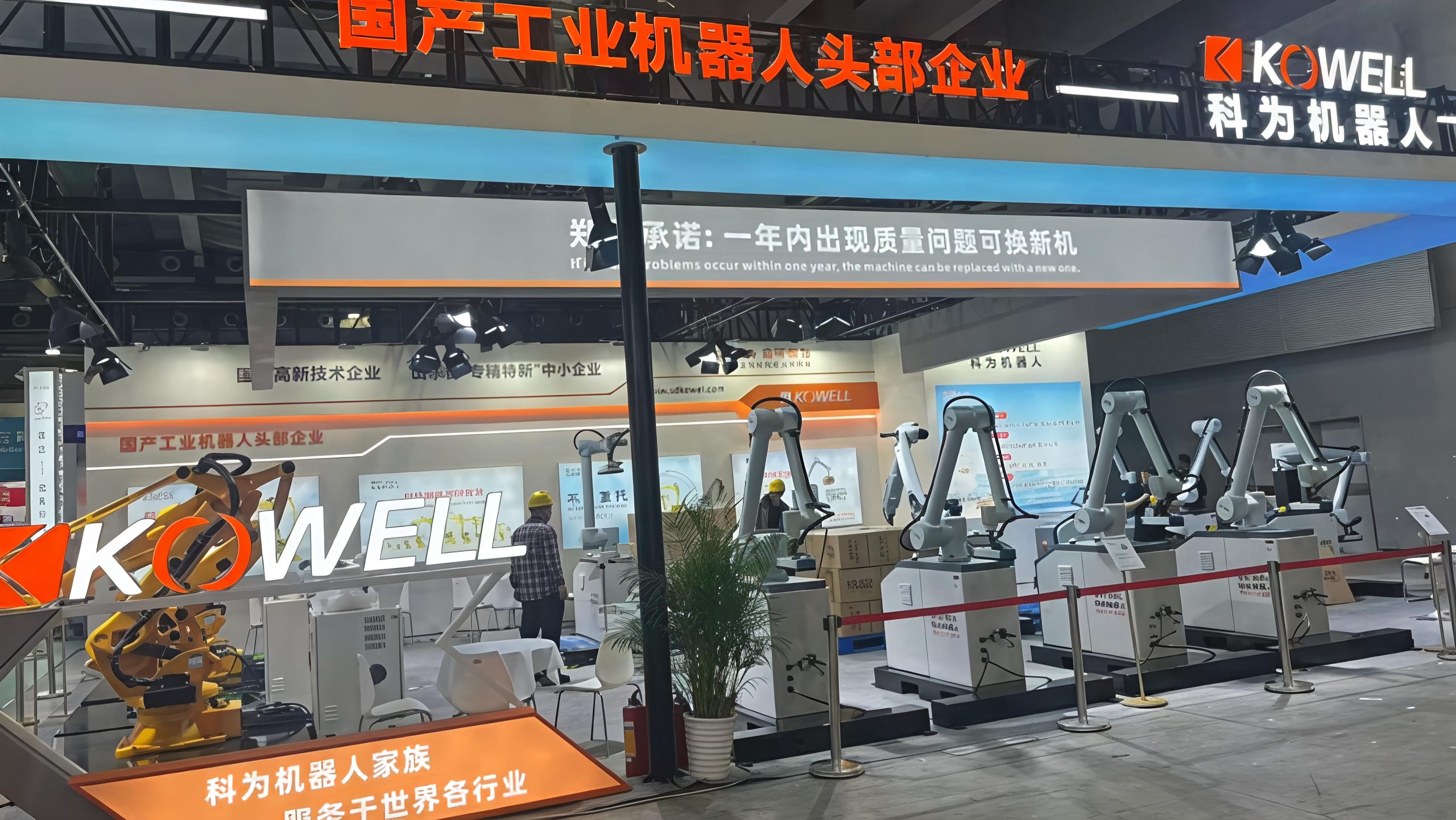

This shift has enabled new industrial units, such as robotic arms and automated equipment, to be integrated into handling processes, assuming higher-intensity operations and more complex collaborative relationships. They not only replace manual labor at the physical level but also become the regulating valves of the manufacturing chain at the information level.

2. The Chain Effect of Structural Adjustment

The structural adjustment of the handling unit is not an isolated event, but rather the starting point for the reorganization of the entire system.

Rhythm Redistribution: When the handling process is equipped with intelligent scheduling capabilities, the production rhythm is no longer dependent on a single process, but is determined by the coordination of the entire chain.

Redefining Connections: The introduction of a new generation of industrial equipment is gradually blurring the boundaries between handling and processing. The handling unit serves as both a connection point and a new process node.

Meaning Beyond Efficiency: Adjustments to the handling process are not just a matter of speed; they are also about stability and predictability. The core of manufacturing logic has shifted from "local speed" to "global balance."

This chain effect has led to the emergence of a new logic within the manufacturing system: handling is no longer a supporting role, but rather the "undercurrent" of the manufacturing chain, influencing the overall flow pattern.

3. The Interaction between the Handling Unit and the Manufacturing Model

Under the new manufacturing model, the handling unit becomes a vehicle for multi-level interaction.

It works with automated equipment to ensure process continuity and avoid interruptions in production;

It collaborates with robotic arms to enable flexible transfer of materials in different forms;

It synchronizes with information systems to ensure that data flow matches material flow. This interaction has transformed the handling process from being solely dependent on the process to becoming increasingly embedded in the core of the manufacturing model. The handling unit now serves as a logical regulator, making the entire system more resilient to fluctuations and changes.

4. Reshaping from Execution to Logic

If handling once played an executive role, today's handling unit is evolving into a logical one. Through structural adjustments, it is changing not only the flow of materials but also the core of manufacturing logic.

In the human-dominated era, handling emphasized "task completion";

In the equipment-assisted era, handling pursued "speed improvement";

Today, with the upgrade of industrial equipment, handling emphasizes "system coordination."

This shift in role enables the handling unit to serve not only the process but also the stability and reshaping of the entire system. Its deep integration with the manufacturing logic has made it a crucial variable driving industrial upgrading.

5. Forward-looking Perspective: Significance Beyond the Chain

The structural adjustments to the handling unit bring not only improvements to the manufacturing model but also a shift in industrial logic. This foreshadows that future manufacturing will no longer be about single-point breakthroughs, but about chain collaboration; no longer about local acceleration, but about overall reshaping. This change will have several profound impacts:

Improved industrial chain robustness: Handling units, through logical adjustments, mitigate the impact of unexpected fluctuations on the system.

Redrawing manufacturing boundaries: With the integration of handling and processing, manufacturing boundaries are being redefined, and the boundaries between process and logistics are gradually dissolving.

Restructuring the human-machine relationship: With robotic arms and automated equipment taking over some handling tasks, human labor is freed from repetitive labor, allowing them to focus more on collaboration and management.

Conclusion

Manufacturing transformation is often not triggered by a single technology, but rather driven by adjustments to multiple subtle links. The structural adjustment of handling units is such a key factor: seemingly unassuming, it can transform the direction of manufacturing logic through a chain reaction.

In the future, whoever can first understand and reconstruct this logic will seize the initiative in manufacturing competition. The handling unit is becoming a key variable hidden deep within the manufacturing system.

Online Consultation

Hello, the current customer service is offline. You can leave your contact information and the staff will respond to you as soon as possible!