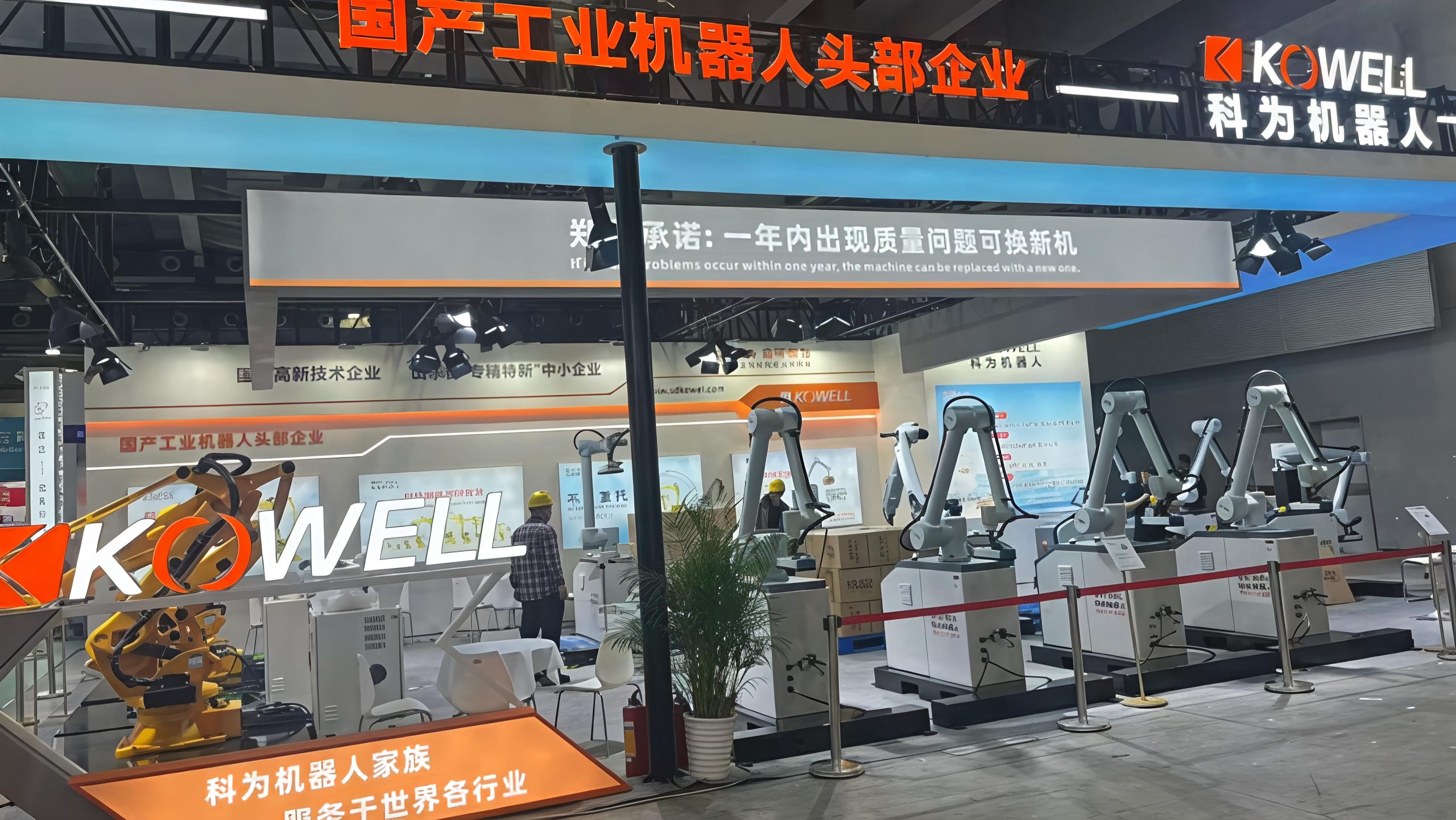

The industrial expo booms, and the momentum of innovation surges. With the 25th China International Industrial Fair (CIIF) already halfway through, the Kewei Robot booth, with its distinctive positioning of "technology leadership, practical implementation," has become the center of attention. The steadily increasing number of visitors and the in-depth, focused technical discussions not only demonstrate the industry's high recognition of Kewei Robot's innovative capabilities in intelligent manufacturing, but also highlight the market's strong expectations for the independent development of China's high-end equipment.

As an innovative pioneer in intelligent manufacturing, Kewei Robot, with its forward-looking strategic vision of "Intelligently Leading the Future," is writing a new chapter in the high-quality development of China's intelligent manufacturing through technological breakthroughs at this global industrial exchange event.

1. Booth Highlights: Build Effective Interactions with Scenario-Based Technology Demonstration to Address Industry Pain Points

As the exhibition enters its mid-term, the global industry's focus is shifting from "technology demonstrations" to "value realization." Kewei Robotics' "Dynamic Demonstration Zone," with its innovative model of "highly realistic production line scenarios + full-process technical analysis," continues to attract industry elites.

Utilizing a digital twin-driven production line replication system, the technical team recreated typical production scenarios in core industries such as automotive parts and food and beverages at a 1:1 scale. Through real-time data interaction and dynamic working condition simulation, Kewei Robotics' technological breakthroughs in "high-speed, high-load, and high-flexibility" scenarios were vividly demonstrated. From millimeter-level positioning accuracy for precision gripping to path planning under complex working conditions, each demonstration directly addressed the three core pain points of the industry: efficiency bottlenecks, high costs, and insufficient flexibility. Each round of technical exchanges focused on the entire lifecycle of "demand diagnosis, solution design, deployment, implementation, and operations and maintenance," aiming to provide customers with quantifiable, implementable, and iterative automation upgrade solutions, truly achieving the goal of "technology demonstration as value verification."

2. Core Technology Breakthrough: The Four-Axis Large-Payload Robot (KW1120M-2400) Reshapes Industry Standards and Defines a New Paradigm for Heavy-Duty Material Handling

At this Industrial Expo, KW Robotics' flagship product, the four-axis large-payload robot (KW1120M-2400), leveraged disruptive technological innovations to become the core vehicle for defining new standards in heavy-duty material handling.

Based on a PLC intelligent motion control system, this robot utilizes KWW's independently developed multi-axis collaborative motion algorithm and dynamic trajectory optimization model to achieve trajectory adjustment during high-speed operation. While maintaining a motion accuracy of ≤±0.2mm, it achieves a significant breakthrough in hourly throughput, increasing efficiency by over 25% compared to similar products in the industry.

Based on its industrial-grade, high-rigidity body design, the robot is currently widely used in core areas such as intelligent food and beverage warehousing, precision furniture panel handling, and heavy-duty component assembly, providing a high-precision, reliable, and flexible autonomous equipment solution for industrial heavy-duty material handling.

3. Full Lifecycle Service System: Building a Trusted Barrier for High-End Equipment with "Quality as a Foundation + Service as a Guarantee"

Kewei Robotics understands that the value of industrial robots lies not only in their technology but also in reliable assurance throughout their entire lifecycle. Driven by the principle of "helping customers maximize the value of our products," Kewei has established an "end-to-end, full-process service system." With rigorous standards and innovative service models, Kewei provides customers with comprehensive support from technology selection to operational support.

Full-Dimensional Quality Control System: Establishing a three-level quality control standard encompassing "R&D, Production, and Delivery," each device undergoes over 200 hours of real-world simulated testing, 150+ precision assembly steps, and 80+ performance indicators (including motion accuracy, load capacity, and other core parameters). Verified by 72 hours of full-load operation, this ensures zero-defect delivery and guarantees product reliability from the ground up.

Industry Warranty Policy: Based on actual user needs, Kewei introduces a "one-year replacement for quality issues" warranty, breaking the industry's standard warranty period. With a "daring commitment, genuine guarantee," Kewei reduces investment risk for customers and demonstrates confidence in our proprietary technology. A nationwide rapid response network: We have established over 50 service locations nationwide, integrating our two major R&D centers in Shanghai and Shandong to form a rapid response mechanism of "local service + headquarters support." We promise on-site service within 48 hours. Simultaneously, our remote fault diagnosis system enables real-time monitoring of equipment operating data, fault warnings, and remote debugging, minimizing customer downtime losses.

4.Countdown to Opportunities: We sincerely invite you to explore the new blue ocean of intelligent manufacturing and anchor the future of industrial upgrading.

The 25th China International Industry Expo is two days away, and Kewei Robotics' booth 7.1HC190 continues to unleash its innovative momentum. We sincerely invite global industry partners and experts to join us for an in-depth interactive experience featuring one-on-one technical discussions, customized solution demonstrations, and real-world performance trials. We will explore the path to intelligent manufacturing implementation.

Experience the technical performance of core products like the KW1120M-2400 under real-world conditions and gain a firsthand understanding of the innovative strength of China's independent high-end equipment.

Communicate face-to-face with Kewei Robotics experts to develop tailored automation upgrade solutions based on your company's actual production needs.

Learn more about Kewei's cutting-edge technology portfolio in areas such as high-payload robots, flexible automated production lines, and digital twin operations and maintenance, and grasp the latest trends in intelligent manufacturing.

As a staunch practitioner of intelligent manufacturing in China, Kewei Robotics has always prioritized technological independence, high-end products, and scenario-based services. We are committed not only to showcasing technological achievements that rival those of other brands in the industry, but also to driving the transformation of technology into industrial value. Going forward, Kewei will lead in breakthroughs in more core technologies, empowering the global manufacturing industry with innovation, and working with partners to achieve a winning future in intelligent manufacturing.

Online Consultation

Hello, the current customer service is offline. You can leave your contact information and the staff will respond to you as soon as possible!