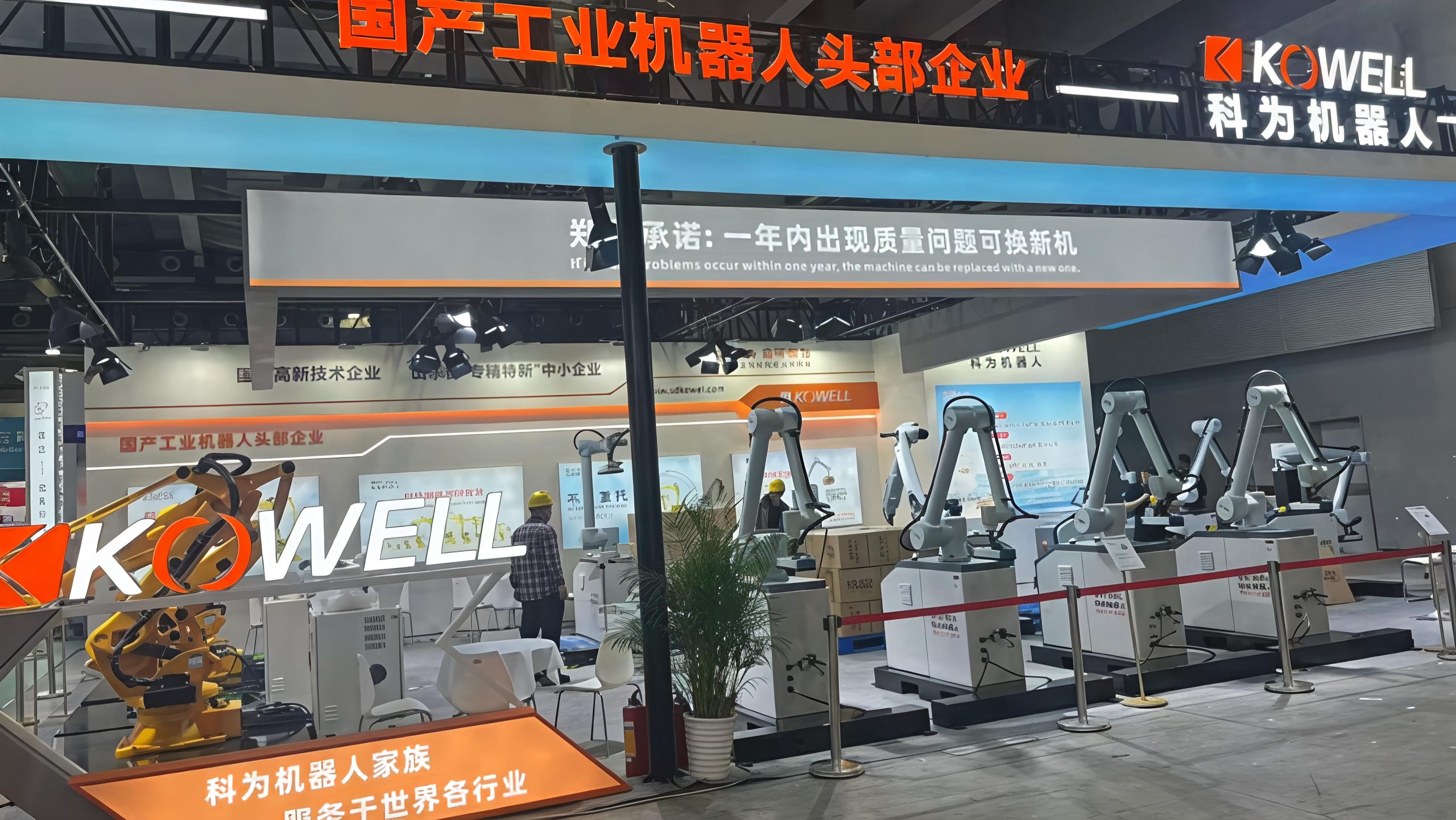

The 25th China International Industry Fair (CIIF) entered its fourth day, and the Kewei Robotics exhibition area (7.1H-C190) remained bustling with activity. As an innovative leader in industrial automation, Kewei Robotics not only showcased the profound innovation capabilities of China's intelligent manufacturing but also demonstrated its strategic development from single-point technological breakthroughs to the construction of an industrial ecosystem. Visitors stopped to interact and engage in lively technical discussions. Dynamic demonstrations of practical application scenarios attracted the attention of numerous industry experts and companies. By the fourth day of the CIIF, the Kewei booth had secured 132 cooperation agreements. Kewei, with its solid technological expertise and innovative practices, showcased the future of intelligent manufacturing.

I. Technology as the Anchor: A Full Matrix Product System Embodying the Core of "Flexible Intelligent Manufacturing"

Focusing on industry pain points, Kewei Robotics showcased its core technology products and solutions in areas such as palletizing, welding, and loading and unloading:

- Kewei's four-axis robot drives intelligent manufacturing upgrades with "three highs" performance

Equipped with Kewei's independently developed "multi-axis collaborative motion algorithm" and "dynamic trajectory optimization model," this robot achieves over 25% higher processing efficiency than comparable products in the industry, while maintaining a motion accuracy of ≤±0.2mm. Its industrial-grade, high-rigidity body design makes it suitable for core applications such as intelligent food and beverage warehousing, precision handling of furniture panels, and heavy component assembly.

- The core advantages of the intelligent welding robot system are highlighted.

Multi-process compatibility: Compatible with various welding processes, including gas shielded welding, double shielded welding, laser welding, and argon arc welding, it meets the welding needs of diverse materials such as stainless steel, carbon steel, and aluminum alloy.

High Precision and Stability: Repeatable positioning accuracy reaches ±0.05mm, ensuring consistent and aesthetically pleasing weld formation. The highly rigid design and high-precision servo drive system ensure precise and stable welding.

Aerial Operation Capability and Protection: The long reach design accommodates the welding needs of large components and complex spatial structures. With an IP67 industrial-grade protection rating, it easily withstands welding spatter, dust, and humid environments.

- Six-Axis Robot Flexible Adaptability Empowers Loading and Unloading

High-Precision, High-Speed Collaboration: The high-precision servo drive and six-degree-of-freedom joint design achieve ±0.05mm repeatability, facilitating complex tasks and motion control.

Flexible Adaptability: The robot supports the rapid replacement of various end effectors, such as suction cups and grippers, flexibly adapting to diverse workpiece types and production needs, including boxed, bagged, and barreled parts. It can integrate handling, palletizing, loading and unloading, and custom automated production processes, meeting the needs of industries such as food, pharmaceuticals, consumer electronics, and daily chemicals, supporting flexible production and rapid changeovers.

Environmental Tolerance: Adaptable to industrial environments, it operates continuously and stably within a wide temperature range of 0°C to 45°C, ensuring continuous production. 4. "Zero-Programming" Intelligent Interactive Terminal

Operators can complete stack modeling and task deployment using gestures and swipes on the 15.5-inch touchscreen, achieving "what you see is what you get" zero-programming operation. Ordinary workers can even configure new tasks after learning, significantly lowering the operational barrier to entry.

A built-in database of standard stack types for six major industries, including food, building materials, and chemicals, supports flexible access to over 100 custom recipes, enabling rapid response to diverse production needs.

II. Value Verification: Recognized Full Lifecycle Service System

Kewei Robotics not only provides high-performance products but also prioritizes customer value throughout its lifecycle:

Reliability Verification: Products undergo rigorous testing to ensure long-term, stable operation in harsh industrial environments, effectively reducing the risk of downtime.

Localized Service and Rapid Response: Leveraging over 50 service locations nationwide and collaborating with technical teams in Shanghai and Shandong, we establish a rapid response mechanism to promptly address customer needs and minimize downtime losses.

Service Commitment: We offer a one-year replacement warranty for quality issues, providing customer support and demonstrating confidence in our technology.

III. Concluding Soon: A Warm Invitation to the Intelligent Manufacturing Feast

The CIIF will close tomorrow, and we look forward to welcoming you to the Kewei Robotics booth:

► Experience the performance and applications of Kewei's various robots in person.

► Speak face-to-face with our technical experts to discuss customized automation solutions based on your actual production needs.

► Gain an in-depth understanding of Kewei's cutting-edge technology portfolio in areas such as large-load robots, flexible automated production lines, intelligent welding, and loading and unloading.

Kewei firmly believes that innovation stems from understanding the industrial landscape and exploring the potential of technology. We not only provide automation equipment, but also look forward to working with partners from all walks of life to build an open, collaborative, and sustainable intelligent manufacturing ecosystem. We look forward to working with you to participate in industrial transformation through innovation and create value together in the new global manufacturing landscape.

Online Consultation

Hello, the current customer service is offline. You can leave your contact information and the staff will respond to you as soon as possible!

![[CIIF Day 4: Technology In-Depth] Kewei Robotics Drives Intelligent Manufacturing with Innovation, Leading the Wave of Industrial Transformation](https://cdn.cnyandex.com/kw_en/uploads/bannercon-2.jpg)